Back-to-Back Fulfillment: Detailed Simulation in Oracle Cloud

Introduction

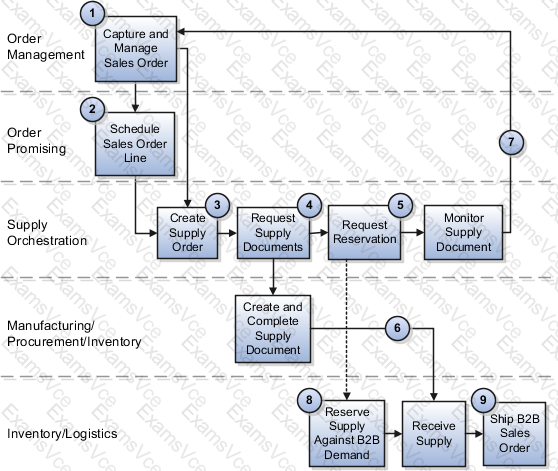

Back-to-back (B2B) fulfillment is a process where supply is created only after a sales order is placed. The supply is specifically reserved for that order and remains linked until fulfillment is completed. Unlike regular inventory processes, back-to-back fulfillment ensures that supply is directly tied to a customer demand, optimizing inventory management while maintaining customer satisfaction.

Key Oracle Fusion Cloud Applications Involved

Back-to-back fulfillment integrates multiple Oracle Fusion Cloud applications, including:

Oracle Order Management (for sales order processing)

Oracle Procurement (for external supply sourcing)

Oracle Manufacturing (for in-house production)

Oracle Inventory Management (for warehouse operations and fulfillment)

Oracle Supply Chain Orchestration (for coordinating supply processes)

Oracle Shipping Execution (for shipping to customers)

Step-by-Step Back-to-Back Fulfillment Simulation

Step 1: Creation of a Customer Sales Order (Source of Demand)

A customer places an order for a product that is not available in stock.

The sales order is created in Oracle Order Management.

The system checks inventory availability in Oracle Inventory Cloud.

Since stock is unavailable, the Supply Chain Orchestration (SCO) module triggers a supply request.

The system determines the best supply source based on sourcing rules (Buy, Make, Transfer, or On-Hand Reservation).

The sales order line is marked for back-to-back fulfillment, and a supply order is generated.

✅ System Action: The system reserves the sales order and waits for supply to be created.

Step 2: Creation and Fulfillment of Supply (Source of Supply to Warehouse)

Once the supply order is created, the system initiates one of the following supply methods:

Option 1: Buy (Procurement from Supplier)

The system generates a Purchase Requisition in Oracle Procurement Cloud.

The requisition is converted into a Purchase Order (PO) and sent to an external supplier.

The supplier fulfills the order and ships the goods to the fulfillment warehouse.

The warehouse receives the items using Oracle Receiving.

Option 2: Make (Manufacturing in-house or contract manufacturing)

The system generates a Work Order in Oracle Manufacturing Cloud.

The work order is scheduled, and production starts.

Once manufacturing is complete, the finished goods are moved to inventory.

Option 3: Transfer (Move from another warehouse or distribution center)

The system creates a Transfer Order in Oracle Inventory Cloud.

Stock is transferred from a different warehouse or location.

Once received, inventory is updated in the fulfillment warehouse.

Option 4: On-Hand (Reserve Existing Inventory)

If stock is available in the fulfillment warehouse, the system directly reserves the items.

No additional supply request is needed.

✅ System Action: The system updates the sales order and marks it ready for fulfillment once supply is received.

Step 3: Shipment of Sales Order to the Customer

The order is released for picking in Oracle Inventory Cloud.

The picking process begins, and items are packed for shipping.

The shipping team processes the order using Oracle Shipping Execution.

A shipment confirmation is generated, and the order is shipped to the customer.

An invoice is created in Oracle Receivables.

The system marks the sales order as fulfilled and closed.

✅ Final Action: The customer receives the order, and the back-to-back fulfillment process is completed.

Key Benefits of Back-to-Back Fulfillment in Oracle Cloud

✔ Optimized Inventory Management – Stock is acquired only when needed, reducing carrying costs.✔ Improved Order Fulfillment Efficiency – Automated supply chain orchestration ensures smooth operations.✔ Enhanced Customer Satisfaction – Orders are processed quickly, reducing delays and backorders.✔ Integrated Supply Chain Execution – Oracle Fusion applications work together seamlessly.✔ Flexibility in Sourcing – Businesses can choose procurement, manufacturing, transfers, or reservations based on demand.